Verified Supplier

Dongguan city chengxin plastic and rubber raw co.,ltd.

| Factory

Experience:2010-11-24

Buyer Protection

- Guaranteed Secure Payments on Every Order

- Refund if your item is not delivered or as described

- Buyer Protection after order confirmation

Latest Browsing

Product Details

- Size: 0.25cbm

- Place of Origin: China

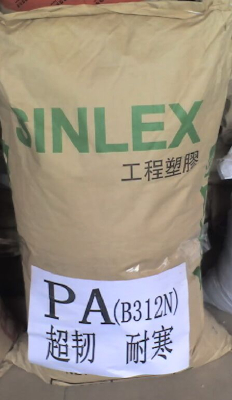

- Brand Name: chengxin

- Model Number: 100FR NC

- Weight: 25.000 kg

Plastic raw material CO., LTD for PA6 series raw materials itemdescription: polyamide 6 or nylon 6 (PA6) formula: [NH - (CH2) 5 - CO] n- description: translucent or opaque milk white crystalline polymerfeatures: thermoplastic, light weight, good toughness and resistance tochemicals, and good durability Huang Huoyan combustion identificationmethods: blue background, burning plant flavor solvent experiment:resistance to cyclohexanone and aromatic solvent density: 1.13 g/cm3melting point: 215 ℃ heat decomposition temperature: 300 ℃ > balancebibulous rate: 3.5% has good wear resistance, self-lubrication andsolvent resistance. Dense degree: (1.14 1.15 g/cm3) melting point:215-225 ℃ tensile strength: > 60.0 Mpa and long rate: > 30%bending strength: 90.0 Mpa notched impact strength: (KJ/m2) > 5application in industrial production extensive used in the manufactureof bearing, gear, CAM, bevel gear, all kinds of roller, roller, pumpimpeller, fan blades, worm gear, screw, screw, nut, washer, highpressure sealing ring sealing gasket, oil resistant, oil resistantcontainers, shells, hose, cable sheath, slider shearing machine pulleyset, the shaper, cold, electromagnetic assigned seat, Chen equipment,liner, bearing cage, automobile and tractor on various pipeline, piston,ropes, transmission belt, textile machinery industry equipment zero fog,and daily necessities, packaging film, etc. Processing dry processing:because of PA6 is easy to absorb moisture, so dry before processing itis important to note that if the material is packed in waterproofmaterial supply, the capacity should be kept closed. If the humidity ismore than 0.2%, it is suggested that in the above 80 ℃ hot air drying 16hours. If the material has been exposed in the air more than eighthours, Suggestions for temperature is 105 ℃, 8 hours of vacuum drying.Melting temperature: 230-280 ℃, for enhanced varieties of 250-280 ℃.Mold temperature: 80-90 ℃. Mold temperature is significantly affect thedegree of crystallinity, and crystallinity and affects the mechanicalproperties of plastic parts. It's very important for structurecomponents crystallization degree, therefore suggested that moldtemperature is 80-90 ℃. For thin-wall, process long plastic parts alsosuggests applying higher mold temperature. Increase the mold temperaturecan improve the strength and stiffness of plastic parts, but it reducesthe toughness. If the wall thickness is greater than 3 mm, it isrecommended to use 20-40 ℃ low temperature mold. For glass fiberreinforced materials mold temperature should be greater than 80 ℃.Injection pressure: generally between 750-750 bar (depending on thematerial and product design) injection speed: fast (to enhance materialto slightly reduce) the runner and gate: for PA6 solidification time isvery short, so the location of the gate is very important. Gate diameternot less than 0.5 * T T is the thickness of the plastic parts (here). Ifyou use the hot runner and gate size should be smaller than usingconventional flow path, because of the hot runner can help preventpremature solidification material. If use into the gate, the minimumdiameter of gate shall be 0.75 mm. Chemical and physical properties aresimilar in chemical physics properties of PA6 and PA66, however, itsmelting point is lower, and the process temperature range is very wide.Its impact resistance and resistance to better solubility than PA66, butstrong hygroscopicity and more. Because many plastic parts qualitycharacteristics are affected by moisture absorption, so using PA6 designto give full consideration to this product. In order to improve themechanical properties of PA6, often to join all kinds of modifier. Glassfiber is one of the most common additives, sometimes in order to improvethe impact resistance also join the synthetic rubber, such as EPDM, SBRand so on. With no additive products, PA6 contraction between 1% and1.5%. Adding glass fiber additives can reduce shrinkage rate to 0.3%(but and process in the vertical direction but also a little higher).Assembly molding shrinkage is mainly affected by crystallinity andhygroscopic material. The actual shrinkage and plastic parts design,wall thickness and also other relations as a function of processparameters. PA6 and PA66 difference between PA6 performance productmelting point: 210-220 - C decomposition temperature: > 300 C flashpoint: > 400 C: spontaneous combustion temperature > 450 C state:solid particles smelly flavor: no poison, no recycling: can eventuallyprocessing: soil (industrial waste harmless) agent: available to allkinds of fire extinguishing agent (water, foam, powder, CO2, sand)transport: non-dangerous goods, apply to all kinds of transportation Ecstandards: non-dangerous goods PA66 products performance melting point:250-270 - C decomposition temperature: > 350 C flash point: > 400C: spontaneous combustion temperature > 450 C state: solid particlessmelly flavor: no toxic sex: no recycling: can eventually processing:soil (industrial waste harmless) put out the fire agent: available toall kinds of fire extinguishing agent (water, foam, powder, CO2, sand)transport: non-dangerous goods, apply to all kinds of transportation Ecstandards: non-dangerous goods PA6 in industrial application ofpolyamide glass fiber reinforced material can be according to therequirements of the product features added glass fiber content in therange of 5-60%, this kind of material has very good strength, heatresistance, good shock resistance, good dimensional stability and lowwarp, etc.

- Size: 0.25cbm

- Place of Origin: China

- Brand Name: chengxin

- Model Number: 100FR NC

- Weight: 25.000 kg